Lithium Ion Battery Manufacturing

Up to 95% reduction of CO₂ emissions

Up to 66% reduction of dry room energy bills

Extremely low dew point down to -120°C for better safety and quality.

Calculate your battery dry room CO2 emissions

The right way to dry a dry room

Cotes is an independent family-owned business that designs and manufactures adsorption dehumidifiers [dry-air solutions] for all types of industrial applications across the world, focusing on sustainability, efficiency, quality and positive impact.

Lithium-ion battery dry rooms use a lot of energy, up to 43% of total energy consumption in the battery manufacturing process, to keep the dry rooms super dry—that’s a relative humidity of under 1% and dew points ranging from -40°C to -120°C.

Cotes offers an Ultradry-air Solution for battery dry rooms that uses our Cotes Patented Exergic Technology**, enabling massive energy reductions, cost savings, and huge CO₂ emissions reductions of up to 95%.

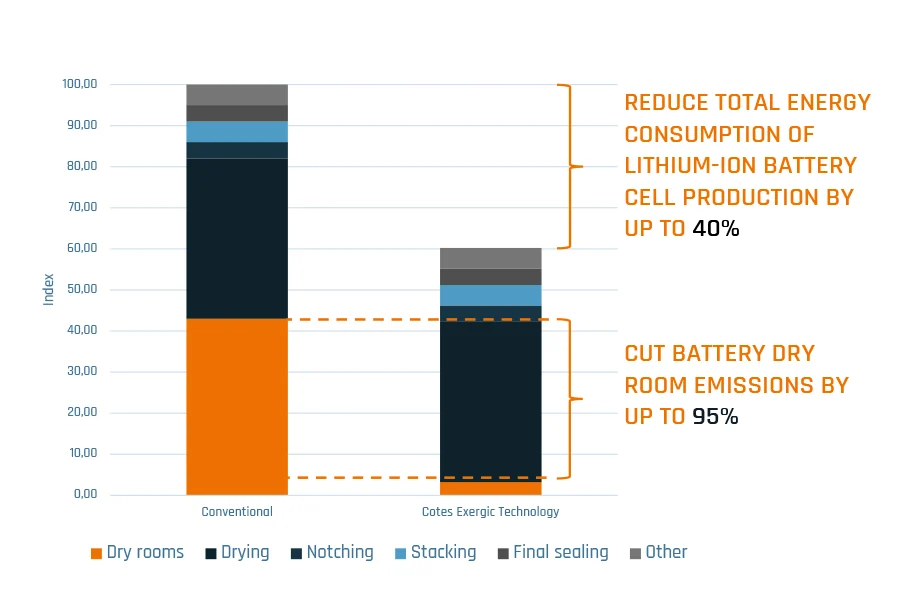

Current process energies of LI-ION battery cell production

The graph below shows the different sources’ energy contributions to the total cell production and battery pack assembly energy in a typical battery manufacturing facility represented as Index 100. [SOURCE] Data from Yuan et al. (2017).

THE MOST SUSTAINABLE ULTRADRY SOLUTION

Reduce CO2 emissions by up to 95%

Battery dry room energy reduction

Up to 43% of the energy consumption for lithium-ion battery cell production is for running dry rooms. Cotes Exergic Technology can reduce this energy consumption by up to 50%.

Sustainable energy sources

Of the remaining 50%, up to 85% can be sourced from low exergy (low temperature) sources, like waste heat, solar thermic panels, heat pumps, etc.

CO₂ emission reduction

The Cotes Exergic Technology enables your battery dry room to be more energy-efficient and gives you the possibility to use a combination of different sustainable energy sources — reducing the CO₂ emission for running a battery dry room by up to 95%

COTES EXERGIC TECHNOLOGY

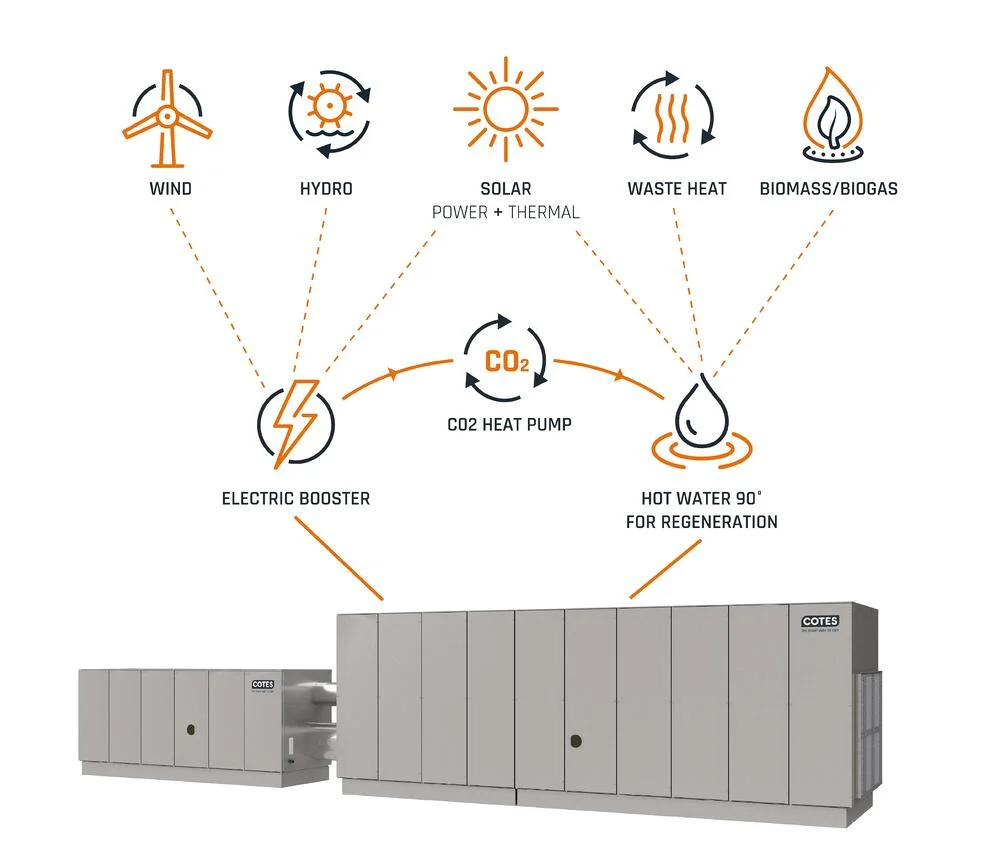

Choose a combination of different sustainable energy sources

The issue with current non-Cotes dehumidification is their high dependency on only electricity and gas with very ineffective air-drying processes at high temperatures makes for a volatile and unsafe process environment. Cotes Exergic Technology gives you a competitive advantage by saving up to 66% on your dry room energy bills, reducing up to 95% of dry room CO2 emissions, and an ultradry system that operates at an extremely safe low dew point as low as -120°C.

How it works

With the Cotes Exergic Technology, you can utilize a combination of sustainable energy sources to achieve considerable energy cost savings and large carbon footprint reductions. All you need for Cotes Exergic Technology to work is hot water heated by a sustainable energy source:

- Waste heat (District heating or waste heat from elsewhere in the li-ion battery production)

- Biomass or Biogas (if available and sustainable)

- Solar thermal panels

- CO₂ Heat Pump used for both heating and cooling. Pay once and use twice.

- Electricity (From sustainable energy sources, i.e., wind power, hydropower, solar power and/or nuclear power)

- Gas **

**Cotes does not recommend or consider gas as a source of sustainable energy due to the environmental footprint. We recommend utilizing energy for the hot water from sustainable or “green” energy sources instead. However, if gas is a requirement, the water can come from a central gas boiler.

Why use hot water?

Cotes Excergic Technology uses hot water because it enables flexibility, makes your dry room operations safer, and has low installation costs—all you need is hot water [80-90°C].

Because the energy to heat the water can come from a combination of sustainable energy sources and can be changed in the future if the price of energy changes, it makes the Cotes Exergic Technology more sustainable and more future proof. This flexibility is not possible if the dehumidifier is built for gas regeneration specifically.

Cotes Exergic Technology is highly efficient. We are able to provide a dew point of -120°C for an unstaffed dry room and -70°C for a manned room.

The Cotes Exergic Technology is less vulnerable to toxic leaks and has a high safety margin running nominal conditions at low temperatures. Running optimal conditions at low temperatures (80-90°C) allows the electric booster inside the dehumidifier to increase the drying capacity when needed without jeopardizing the effectiveness or the safety of the system. Our closest competitors run optimal conditions at maximum temperature (140-180°C) making it vulnerable to any fluctuation in humidity and drying capacity.

BENEFITS

Better control and lower costs

- Exceptional control of cleanroom manufacturing conditions

- Better electrolyte performance, better product quality

- Reduced energy consumption, lower operating costs, and lower carbon footprint

- Maximum production uptime and lower service and maintenance costs

+150

NUMBER OF BATTERY DRY ROOMS AROUND THE WORLD USING COTES ULTRADRY ADSORPTION DEHUMIDIFIERS

32K

EACH UNIT IS DESIGNED TO HANDLE LARGE VOLUMES OF AIR OF ~32.000 M3/H

FEATURES

Performance and reliability

- Exceptional reliability – important for operations-critical environments

- Easy to configure to specialist requirements in lithium-ion battery manufacture, even with dew points as low as -120°C (in unmanned dry room)

- Designed to achieve exceptionally low energy consumption and operating costs

- Available with advanced monitoring and control systems for maximum flexibility

THE CHALLENGE

When you don’t have the right dry-air solution

To safely manufacture lithium-ion batteries you need a relative humidity of less than 1% because of the delicate chemistry involved. Maintaining this %RH is energy-intensive and costly if you don’t have the right dry-air solution.

DANGEROUS GASSES

Lithium reacts intensely with water, forming dangerous combinations of lithium hydroxide, highly flammable hydrogen and heat

PRODUCT QUALITY ISSUES

Exposing lithium to humidity levels above 1% impacts quality, performance and lifespan of batteries

HIGH ENERGY COSTS

Energy expended to control humidity results in high operating costs and affects profit margins

PRODUCTION OUTPUT

Any humidity irregularities can affect your battery production and output

INCREASED COSTS

Service and maintenance costs increase to counter the effects of humidity without the right ultradry-air solution

NEGATIVE ENVIRONMENTAL IMPACT

Inefficient processes that use excessive energy from unsustainable sources of energy only lead to further negative environmental impact